LINCOTEK Equipment Partnership

July 13, 2020

Uniquecoat Technologies LLC is pleased to announce a distribution partnership with LINCOTEK Equipment, Via Mistrali 5, 43046 Rubbiano, PR, Italy. LINCOTEK (formerly Artec est. 1996) is now an authorized distributor of Uniqucoat Technologies products and services. Lincotek Equipment, a member of the Lincotek Group, is a leading Italian manufacturer of complete coatings solutions for Thermal Spray, diffusion coatings and related processes.

“Our new partnership represents a tremendous opportunity to further the growth of HVAF equipment and coatings across Europe. We are excited about the opportunity to work together, LINCOTEK is an outstanding distributor providing coating solutions, turnkey systems and service throughout Europe”. – said Viatcheslav Baranovski, President of Uniquecoat Technologies LLC.

Uniquecoat Technologies LLC is pleased to announce a distribution partnership with LINCOTEK Equipment, Via Mistrali 5, 43046 Rubbiano, PR, Italy. LINCOTEK (formerly Artec est. 1996) is now an authorized distributor of Uniqucoat Technologies products and services. Lincotek Equipment, a member of the Lincotek Group, is a leading Italian manufacturer of complete coatings solutions for Thermal Spray, diffusion coatings and related processes.

“Our new partnership represents a tremendous opportunity to further the growth of HVAF equipment and coatings across Europe. We are excited about the opportunity to work together, LINCOTEK is an outstanding distributor providing coating solutions, turnkey systems and service throughout Europe”. – said Viatcheslav Baranovski, President of Uniquecoat Technologies LLC.

HVAF - High Velocity Air Fuel Technology

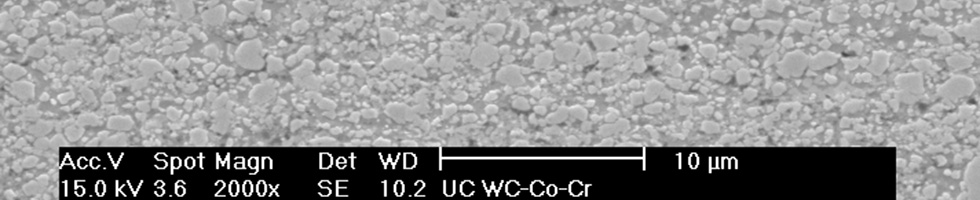

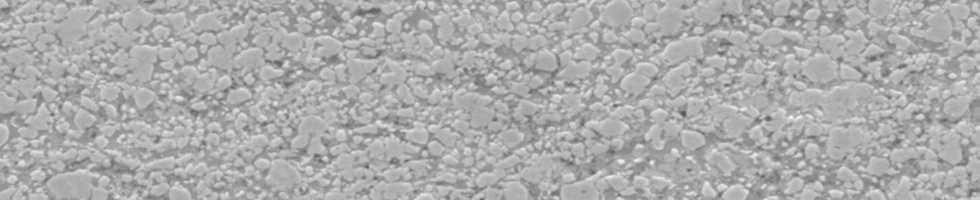

HVAF or High Velocity Air-Fuel is a thermal spray process for deposition of high performance coatings from cemented carbide and metal powders for protection of parts against abrasion, erosion and corrosion.

» read more »

High Velocity Air Fuel:

- a derivative of conventional HVOF

- uses compressed air instead of oxygen

- higher spray rates and deposit efficiency

- faster spraying and lower application cost

- harder, better performing coatings due to the "warm spray" nature of the process

- surface preparation is done with the spray gun

» read more »

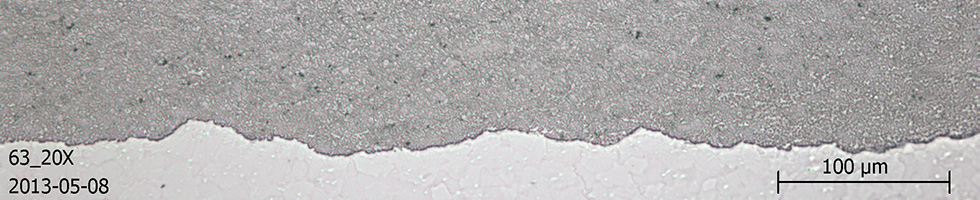

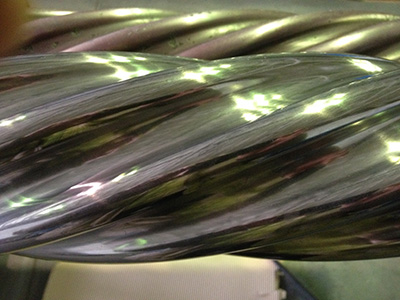

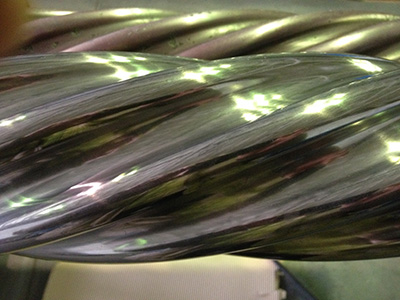

WC Protective Coating applied with M3™:

Industrial Powder Feeders

Gravimetric and volumetric powder feeders for use with:

Gravimetric models feature a user-friendly touch screen interface that allows the operator to set the feed rate in grams per second, grams per minture, kilograms per hour, or pounds per hour.

All powder feeder models contain no wearing seals and require no routine replacement of consumable parts, providing years of dependable operation in the harshest industrial conditions.

» read more »

- Thermal Spray

- HVOF

- HVAF

- Plasma

- Cold Spray

- Laser Cladding

- Industrial Applications

Gravimetric models feature a user-friendly touch screen interface that allows the operator to set the feed rate in grams per second, grams per minture, kilograms per hour, or pounds per hour.

All powder feeder models contain no wearing seals and require no routine replacement of consumable parts, providing years of dependable operation in the harshest industrial conditions.

» read more »

Twin-Wire Arc Spraying

Twin-wire arc spray systems for spraying solid and cored wires of 1.6 mm to 2.3 mm in diameter.

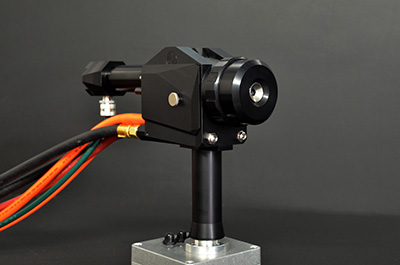

ArcMaster 300™ is a simple and reliable twin-wire arc spray system with a dependable pull mechanism incorporated in a light-weight, durable spray gun.

Simple to use and maintain the system delivers consistent quality coatings from all standard wires.

» read more »

ArcMaster 300™ is a simple and reliable twin-wire arc spray system with a dependable pull mechanism incorporated in a light-weight, durable spray gun.

Simple to use and maintain the system delivers consistent quality coatings from all standard wires.

» read more »

HVAF Arc Spraying

HVAF Arc 300™ is a unique twin-wire arc spray system that provides superfine atomization of sprayed wire by a reducing HVAF jet, creating very dense, low porosity coatings with lower oxide content.

» read more »

» read more »