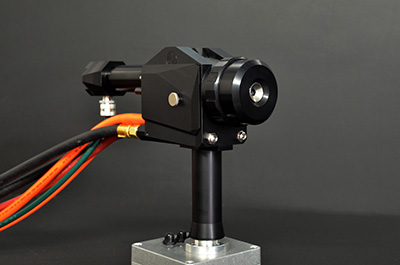

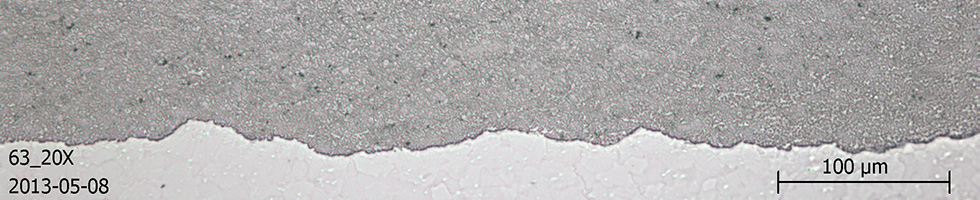

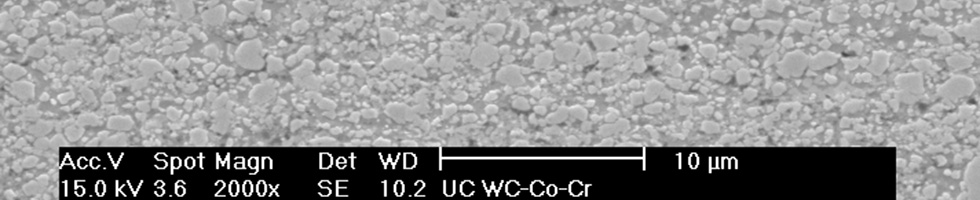

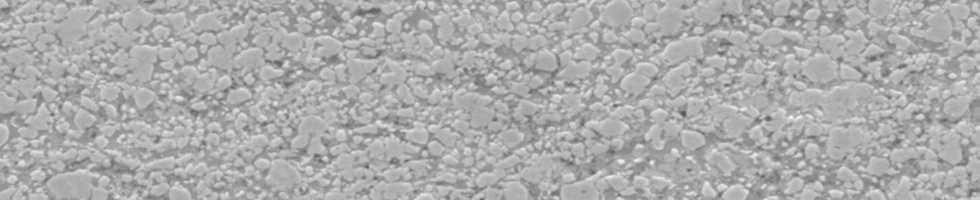

The HVAF Arc spray gun produces dense and finely structured coatings from solid and cored wire stock. The gun employs an electric arc to melt the wires and an HVAF jet to atomize and accelerate the fused particles. The spray head, which is the size of a conventional arc head, includes a toroidal combustion chamber atomizer surrounding the wire tips. A hot ceramic insert activates air-fuel combustion and makes it stable within an extremely short chamber. Exhaust gases are directed into the arc zone. The resultant high velocity jet atomizes molten material, accelerates particles, and propels them toward the substrate where they form a coating. This jet is low in oxygen content and protects the liquid metal from oxidation in the arc zone. Dense, very finely structured coatings with an even distribution of elements and phases are formed due to the atomization of spray wires to extremely fine particles, their acceleration to high velocities, and in-flight protection against oxidation. While this is beneficial to all sprayed materials, the HVAF Arc gun demonstrates exceptional performance while spraying cored wires. Hard-face coatings of such wires exhibit improved resistance to erosive and abrasive wear, and in many applications they can replace hard chrome plating.

HVAF Arc can be ordered in a high feed rate (HFR) configuration that is optimized for materials with low melting points, such as zinc and aluminum.

Applications

- Wear resistance

- Anti corrosion

- Repair and maintenance

- Corrosion protection of steel and naval constructions

- Corrosion protection of concrete structures

- Corrosion protection off shore

Features

- Very dense, low porosity coatings

- Superfine particle atomization

- Air-cooled toroidal combustion chamber-accelerator with jet velocity of 800 m/sec

- Durable design for harsh industrial environments

- Pull mechanism with a powerful DC motor with planetary gear head enclosed in a dust proof protective housing provides smooth feeding of wire stock and ensures a stable arc

- Hardened steel wire guides

- Wire feed rollers provide reliable wire grip for slip-free operation with both hard solid and malleable cored wires

- Maintenance free worm gearbox with life expectancy of 10,000-12,000 hours

- Tungsten-copper alloy contact tips

Specs

|

| 1.6-2.3 mm | 300 A | 50 SCFM @ 125 PSI |

|

| Current | 450 A |

| Voltage | 18 - 38 V |

| Weight | 174 kg |