M2™ Supersonic HVAF Spray Gun

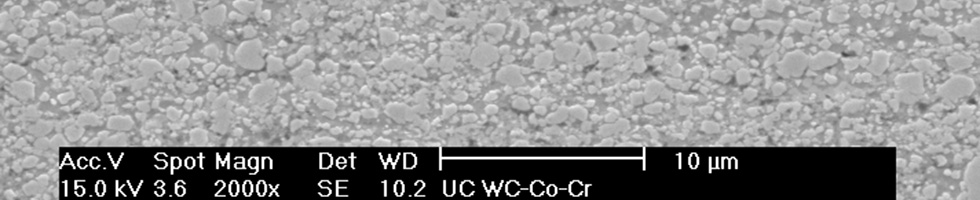

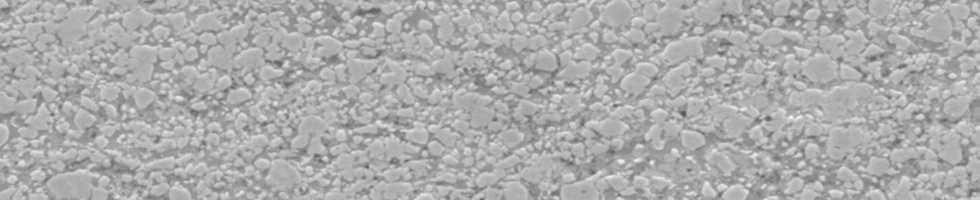

The M2™ supersonic HVAF single nozzle spray gun is designed specifically for cost-effective deposition of high quality cemented carbide, metal and metal alloy coatings. The M2™ can apply all HVOF powders, as well as special HVAF cuts (-30+5 μm, -30+10 μm), and superfine cuts (-15+5 μm, -10+5 μm). Metals and metal alloys can also be effectively applied.

| Powder | Cut | Velocity | D.E. | Spray Rate |

| WC-based powders | -30+5 μm | ~ 935 m/s | 46-55% | 30 kg/h max |

| CrC-based powders | -25+5 μm | ~ 1040 m/s | 45-55% | 18 kg/h max |

| Hardfacing Alloys | -45+15 μm | ~ 850 m/s | 65-85% | 16 kg/h max |

- WC-based coatings with hardness of up to 1500 HV300

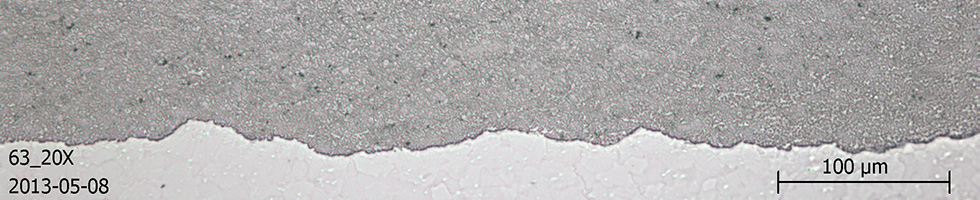

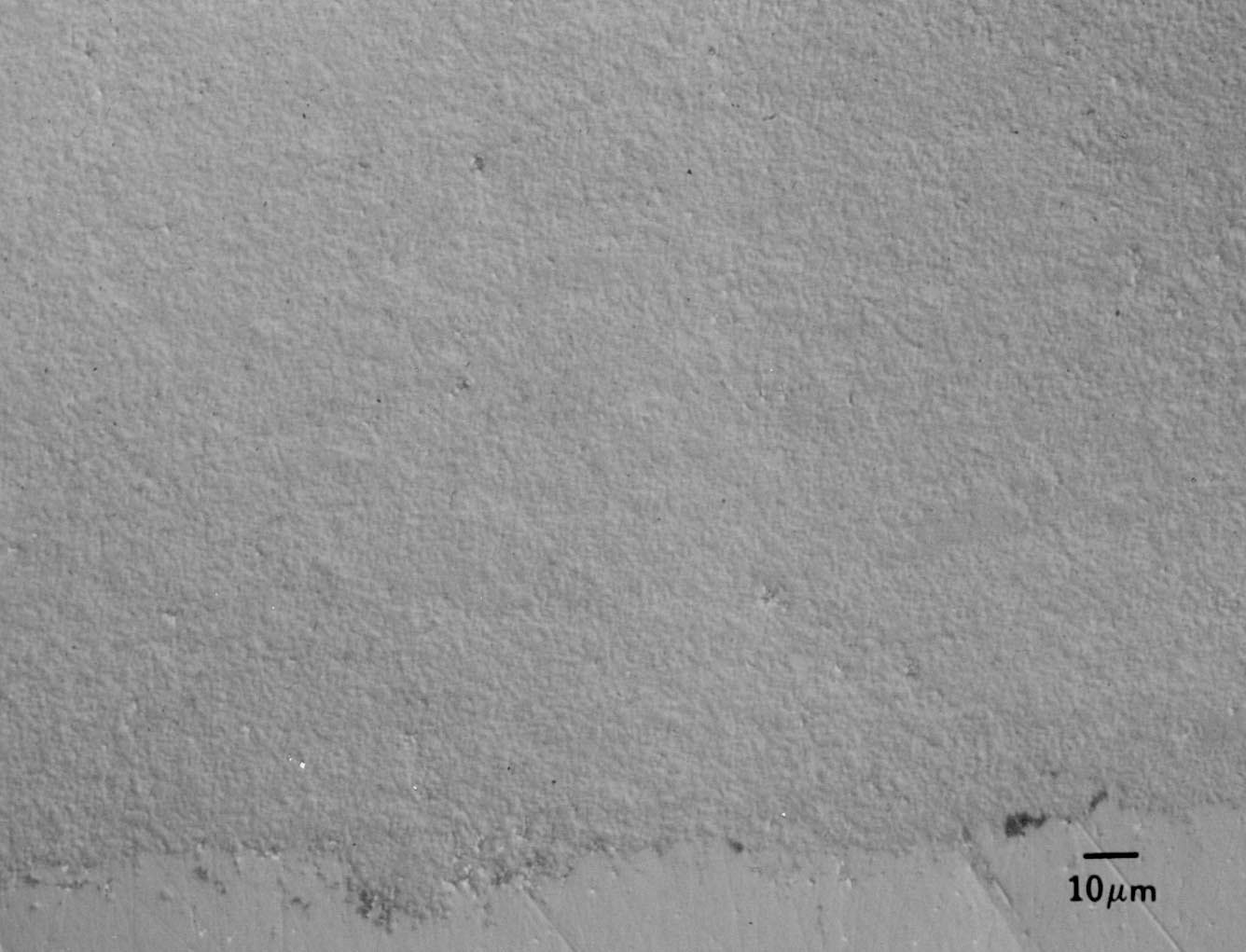

- Coating porosity typically below 0.2%

- Compressive residual stresses in coatings

- Negligible oxide content in coatings (1.5-2 times that of feed stock material)

The M2™ spray gun operates on Propylene or Propane, but also fully supports the use of natural gas, offering flexibility and the option of substantial cost savings while retaining good deposition efficiency. Highly efficient 100% air cooling eliminates the need for a chilled water supply.

The cost of coating application with M2™ is 2-4 times lower compared to HVOF process due to use of air instead of oxygen and high spray rates that reduce spraying time.

Grit Blasting

The M2™ spray gun can also be used to grit blast parts immediately prior to coating application. By supplying grit to the gun and executing the normal spraying sequence on the robot a part can be grit blasted in place. Hot grit blasting may also be similarly perfomed, by supplying grit to a running gun. This high velocity grit blasting offers 20-50 fold reduction in grit consumption, and up to 15 fold reduction in blasting time. For example, a mandrel that normally takes 30 minutes to grit blast, can be hot grit blasted in just under 2 minutes. Hot grit blasting technology permits to substantially increase the bond strength of subsequently applied coatings. Grit options include Aluminum Oxide # 120, 150, 180 or 220, as well as Tungsten Carbide 8-14 µm, 14-26 µm, 26-32 µm.

M2™ Spray Gun

| Fuel Types | Air Consumption | Cooling |

| Propylene, Propane Natural Gas |

200 SCFM @ 125 PSI | 100% air cooled |

- Cost-effective spraying of cemented carbides, metals, metal alloys

- Axial powder injection

- 100% Air Cooling (no water chillers)

- Can spray continuously for hours without stopping

- Low operating cost

- Low consumption of spare parts

- Fast start-up