i7™ Internal Diameter HVAF Spray Gun

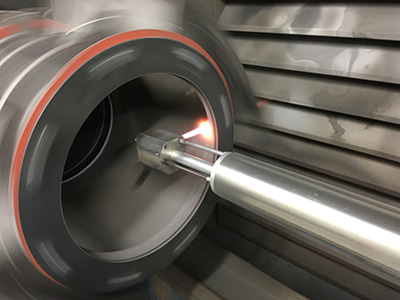

The i7™ I.D. spray gun delivers high performance cemented carbide, metal, and metal alloy coatings for internal diameter applications.

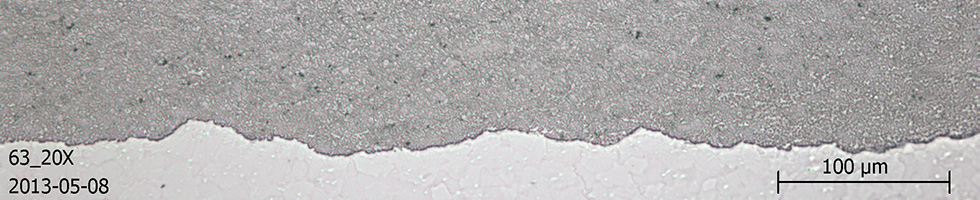

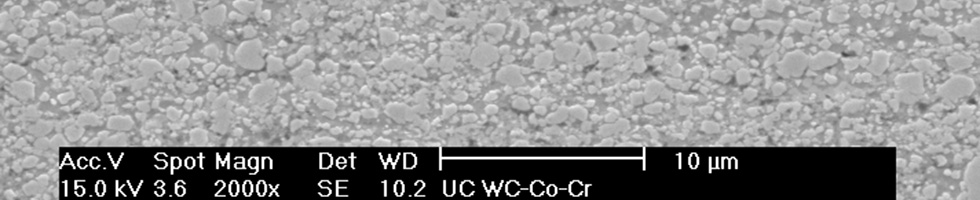

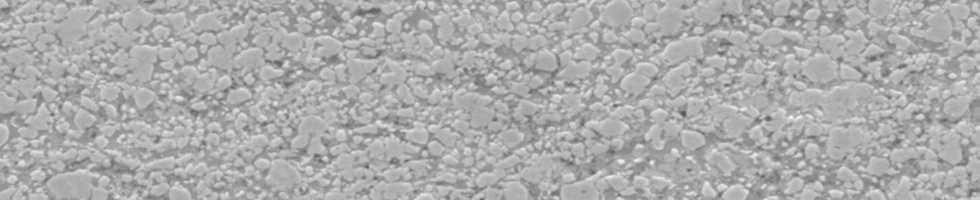

- WC-based coatings with hardness of up to 1550 HV300

- Variable nozzle configuration permits spraying of internal diameters as small as 120 mm

- Coating porosity typically below 1%

- Compressive residual stresses in coatings

- Negligible oxide content in coatings (1.5-2 times that of feed stock material)

- Durable and dependable in operation, the i7 requires minimal maintenance and is ideal for large scale applications.

The i7™ I.D. spray gun operates on Propylene or Propane. Highly efficient 100% air cooling eliminates the need for a chilled water supply.

i7™ I.D. Spray Gun

| Fuel Types | Air Consumption | Cooling |

| Propylene, Propane | 42 SCFM @ 125 PSI | 100% air cooled |

- Spraying of Internal Diameters of 120+ mm

- Cemented carbide coating hardness up to 1550 HV300

- Cost-effective spraying of cemented carbides

- Axial powder injection

- 100% Air Cooling (no water chillers)

- Can spray continously for hours without stopping

- Low operating cost

- Low consumption of spare parts

- Fast start-up

Grit Blasting

The i7™ I.D. spray gun can also be used to grit blast parts immediately prior to coating application. By supplying grit to the gun and executing the normal spraying sequence on the robot a part can be grit blasted in place. Hot grit blasting may also be similarly perfomed, by supplying grit to a running gun. This high velocity grit blasting offers 20-50 fold reduction in grit consumption, and up to 15 fold reduction in blasting time. For example, a mandrel that normally takes 30 minutes to grit blast, can be hot grit blasted in just under 2 minutes. Hot grit blasting technology permits to substantially increase the bond strength of subsequently applied coatings. Grit options include Aluminum Oxide # 120, 150, 180 or 220, as well as Tungsten Carbide 8-14 µm, 14-26 µm, 26-32 µm.