Uniquecoat® M5™ HVAF System

The M5 HVAF System is Uniquecoat’s flagship platform, combining the next-generation, high-thermal-efficiency M5 spray gun, ULTRACOAT-M5 control center, and GDU-M5 gas distribution unit into a fully integrated system.

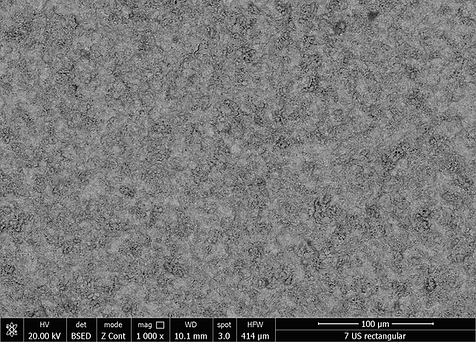

The M5 HVAF System, built around fully independent, mass-flow-controlled gas delivery, provides enhanced process efficiency, wide powder-size versatility, and exceptional coating quality and repeatability. This advanced and highly flexible platform enables end users to apply dense, virtually non-porous coatings with high deposition efficiency when spraying standard HVOF-grade WC- and CrC-based powders.

In addition, the M5 System is an ideal solution for producing impermeable Flash Carbide coatings using ultra-fine HVAF powders, applied with or without hydrogen for improved safety and operational efficiency. In both cases, the resulting coatings exhibit extremely low surface roughness (Ra 1.1–1.3 µm) while maintaining full impermeability, providing effective corrosion protection at significantly reduced coating thicknesses.

Key Features

1. Full Mass-Flow Control of All Process Gases

The M5 HVAF is the only HVAF platform featuring fully independent mass-flow control of all process gases in both single-stage and dual-stage combustion modes. This capability enables:

🟢 One-Touch Startup — Automatic ignition at full operating flow rates eliminates the trial-and-error adjustments typical of pressure-controlled systems; no startup ramp is required.

🟢 Stable Gas Delivery — All gas flow rates are maintained precisely at defined setpoints throughout the entire spray process.

🟢 Highly Reproducible Results — Stored gas-parameter recipes can be recalled for repeat jobs, ensuring consistent coating quality and deposition efficiency across production runs.

🟢 Consistent Results Across Multiple Systems — Process recipes transferred between M5 HVAF units deliver uniform coating performance across all compatible Uniquecoat systems, a capability not achievable with pressure-controlled designs.

2. High-Thermal-Efficiency M5 Combustor and Dual-Stage Combustion with Independent Stage Control

🟢 High Thermal Efficiency — The optimized combustor design improves the completeness of fuel combustion and enhances heat transfer to powder particles, maximizing particle heating while reducing overall fuel consumption.

🟢 Dual-Stage HVAF Combustion — Secondary combustion within the extended nozzle increases total jet energy, improving particle heating and enabling the formation of dense, low-porosity coatings with high deposition efficiency.

🟢 Independent Stage Control — Primary and secondary combustion zones are regulated independently, allowing precise adjustment of jet temperature and energy distribution. This enables particles to reach optimal temperature and velocity, ensuring optimal coating results across a wide range of powder materials.

Uniquecoat M5 HVAF System

M5 HVAF System — Main Components

The M5 HVAF System integrates three core modules — the M5 HVAF Gun, GDU-M5 Gas Distribution Unit, and ULTRACOAT-M5 Control Center — working together for precise combustion control, stable operation, and exceptional coating quality.

You can also add a high quality Uniquecoat gravimetric or volumetric powder feeder to your M5 HVAF system

The system operates on standard LPG fuels (propane or propylene) supplied at 145 psi and up to 0.5 kg/min flow. For consistent gas delivery, use an electric LPG vaporizer and, if needed, an LPG pump to maintain proper pressure under low-temperature conditions. Both units are available from Uniquecoat.

_edited.png)