Legacy HVAF Spray Systems

Built for reliability and long-term value, our legacy HVAF platforms -M2H™, M2™, M3™, and M4™- have delivered proven performance across thousands of hours in demanding industrial environments. Paired with the ULTRACOAT-P pressure-based control console, these systems remain a trusted solution for a broad range of thermal spray applications.

M3/M4/M2/M2H HVAF Systems

M2/M2H/M3/M4 Spray Guns – Durable & Versatile

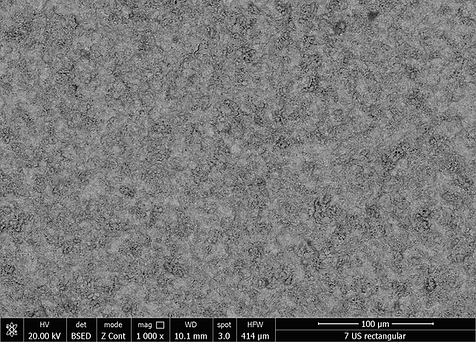

The M3 and M4 spray guns feature Uniquecoat’s proven combustor design, delivering consistent coating quality and long-term system durability. In dual-stage combustion mode, these guns can spray both fine HVAF powders and standard HVOF-grade powders, producing dense, hard coatings with excellent wear resistance.

The M2 and M2H guns utilize a single-stage combustion configuration optimized for spraying HVAF-grade powders and producing Flash Carbide coatings. These models are simple, robust, and highly durable, making them ideal for demanding industrial environments.

ULTRACOAT-P Console – Reliable Pressure-Based Control

The ULTRACOAT-P control center uses pressure-regulated gas delivery, enabling dependable ignition and stable performance for standard HVAF applications. While it lacks the precision of mass-flow systems, it remains a cost-effective and robust solution for many coating needs.

GDU-P – Simplified Gas Management

The GDU-P provides essential gas distribution in a compact and reliable package. It includes separate pressure-regulated fuel lines and a single MFC-controlled carrier gas line—supporting flexible operation across various spray scenarios.

Legacy Performance vs. Next-Gen Precision

ULTRACOAT-P offers dependable pressure control, while the next-generation ULTRACOAT-M platform delivers advanced mass-flow regulation, independent dual-stage combustion control, and unmatched process repeatability.