Uniquecoat® i5™

Internal Diameter HVAF Spray Gun

The i5 I.D. spray gun is designed for internal diameter applications, delivering high-performance cemented carbide, metal, and alloy coatings on internal diameters as small as 65 mm.

The i5 operates on propylene, and its highly efficient 100% air-cooling system eliminates the requirement for a chilled water supply.

The i5 internal-diameter spray gun delivers high-performance carbide, metal, and alloy coatings for internal surfaces.

🟢 WC-based coatings with hardness up to 1200 HV300

🟢 Variable nozzle configuration allows spraying internal diameters as small as 65 mm

🟢 Coating porosity typically below 0.5%

🟢 Compressive residual stresses in deposited coatings

🟢 Negligible oxide content — typically only 1.5–2× higher than that of the feedstock material

🟢 Durable, reliable operation with minimal maintenance requirements

Key Features:

🟢 Axial powder injection – efficient, uniform particle heating and acceleration

🟢 100% air cooling – enables continuous operation without water or nitrogen cooling systems

🟢 Continuous spraying capability – can spray for hours without interruption

🟢 Low operating cost – optimized fuel and air consumption with minimal maintenance

🟢 No oxygen required – safe, environmentally friendly HVAF combustion process

🟢 Highest spray rate in class – delivers exceptional productivity and coating throughput

🟢 Low spare part consumption – long-life nozzles and combustion components reduce cost of ownership

🟢 Fast start-up – ready to spray within seconds for maximum uptime

Uniquecoat i5 I.D. HVAF Gun

Demo Videos of i5 HVAF Gun

i5 HVAF I.D. PROCESS DEMOSTRATION VIDEOS

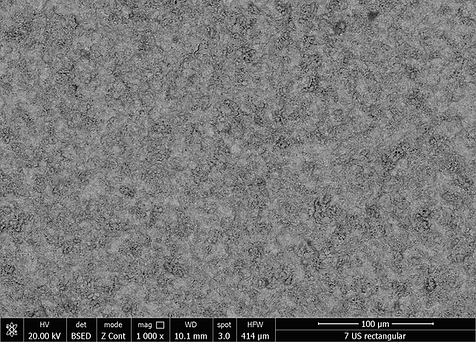

Coating Microstructure

TYPICAL i5 COATING CROSS-SECTION MICROGRAPHS

Average Hardness 1110 HV0.3

Average Hardness 1110 HV0.3

Average Hardness 1203 HV0.3 Porosity: 0.03% via image analysis

Average Hardness 1203 HV0.3 Porosity: 0.03% via image analysis

Cross-sectional EDS (energy-dispersive X-ray spectroscopy) elemental mapping

No oxygen enrichment, no decarburization, and uniform W/Co/Cr distribution — all characteristic of a high-quality HVAF coating. The measured composition and morphology indicate minimal carbide decomposition, confirming low thermal input typical for HVAF vs. HVOF.