Uniquecoat® M4™ HVAF Gun

Air Preheating

Dual-Stage Combustion Design

Dual-stage combustion, combined with air preheating, significantly increases combustion and particle temperature, resulting in higher coating quality and deposition efficiency.

Compared to the M3, the M4 introduces air preheating — process air is routed through the combustion-chamber housing for heating before entering the chamber. This design increases combustion temperature, enhancing particle heating, coating quality, and deposition efficiency, especially when spraying standard HVOF-grade powders.

The M4 gun, like the preceding M3 model, features Uniquecoat’s proprietary dual-stage combustion principle, which creates an “afterburner” effect by extending the effective heating zone across two sequential nozzles. This configuration significantly enhances particle heating, resulting in higher deposition efficiency and coating quality.

The M4 can also be equipped with interchangeable single nozzles for operation in single-stage combustion mode, replacing the dual-stage setup. In this mode, the gun is optimized for fine and ultra-fine powders and is particularly effective for producing impermeable Flash Carbide coatings.

Both the M4 and M3 guns utilize the same set of nozzles, ensuring compatibility and simplified maintenance.

M4

M4 HVAF Gun - Key Features

🟢 Air-preheating system – routes process air through the combustion chamber housing for heating before combustion, increasing flame temperature and improving particle heating, deposition efficiency, and coating quality compared to the M3

🟢 Dual-stage combustion “afterburner” design – extends the effective heating zone, delivering superior particle heating and coating density compared to single-stage combustion HVAF guns

🟢 High coating performance – produces impermeable tungsten carbide coatings with high hardness and negligible W₂C content using standard HVAF powders

🟢 Versatile powder capability – efficiently sprays both standard HVOF powder cuts (15/45 µm) and fine HVAF powder cuts (5/30 µm)

🟢 Configurable nozzle options – sonic or supersonic nozzles, as well as ceramic nozzles of various diameters and lengths, are available to match specific powder sizes and materials for optimal performance

🟢 Quickly configurable operation – interchangeable nozzles allow rapid conversion from single-stage combustion mode for spraying fine and ultra-fine powders to dual-stage combustion mode for processing coarse HVOF-grade powders

M4 HVAF Gun Configurations

The M4 HVAF gun features a modular combustion system that allows quick change between single-stage and dual-stage combustion modes, adapting instantly to different powders and coating requirements.

Single-Stage Combustion — Optimized for Fine & Standard HVAF Powders

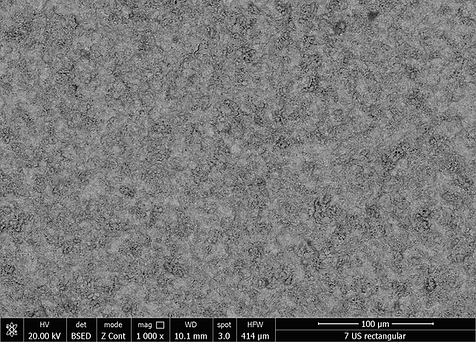

The single-stage combustion configuration excels with ultra-fine powders such as 2/15 µm WC–CoCr, producing thin (15–30 µm), dense, and impermeable coatings with an as-sprayed roughness of Ra 1.2–1.6 µm — ideal for Near-Net-Shape applications and Flash Carbide coatings.

At the same time, it provides high deposition efficiency with all conventional HVAF powders.

Dual-Stage Combustion — Optimized for Standard HVOF Powders

The dual-stage combustion configuration delivers substantially higher heat input to powder particles compared with single-stage operation. By injecting additional fuel into the secondary combustion zone, it creates a staged-combustion effect that elevates particle temperature without introducing additional oxygen into the process air.

This configuration is ideal for standard HVOF-grade powders (15/45 µm), producing dense coatings with superior hardness and bond strength.

Modular Flexibility — One Gun, Two Combustion Modes

Switch seamlessly between single-stage and dual-stage combustion setups in just minutes. From ultra-fine (<15 µm) Flash Carbide powders to standard (–45 µm) HVOF grades, the M4™ system covers the full powder range with maximum efficiency and superior coating quality.