Uniquecoat® i7™

Internal Diameter HVAF Spray Gun

The i7 I.D. spray gun is designed for internal diameter applications, delivering high-performance cemented carbide, metal, and alloy coatings.

The i7 operates on either propylene or propane, and its highly efficient 100% air-cooling system eliminates the requirement for a chilled water supply.

The i7 internal-diameter spray gun delivers high-performance carbide, metal, and alloy coatings for internal surface applications.

🟢 WC-based coatings with hardness up to 1550 HV300

🟢 Variable nozzle configuration allows spraying of internal diameters as small as 120 mm

🟢 Coating porosity typically below 0.5%

🟢 Compressive residual stresses in deposited coatings

🟢 Highest spray rate in class for maximum productivity

🟢 Negligible oxide content — only 1.5–2× higher than that of the feedstock material

🟢 Durable, dependable operation with minimal maintenance, ideal for large-scale production applications

🟢 Axial powder injection – provides uniform particle heating and efficient material utilization

🟢 100% air cooling – simplifies setup and reduces system maintenance

🟢 Continuous operation – can spray for hours without interruption

🟢 Low operating cost – minimal fuel and air consumption with reduced maintenance requirements

🟢 No oxygen required – safe, efficient HVAF combustion process using only air and fuel gas

🟢 Highest spray rate in class – delivers exceptional productivity and coating throughput

🟢 Long-life nozzles and combustion chamber – durable design minimizes downtime and replacement frequency

🟢 Low spare part consumption – extended component lifespan reduces cost of ownership

🟢 Fast start-up – ready to spray within seconds for maximum uptime

i7

i7 I.D. HVAF Gun

i7 Application Examples

i7 HVAF I.D. PROCESS DEMOSTRATION VIDEOS

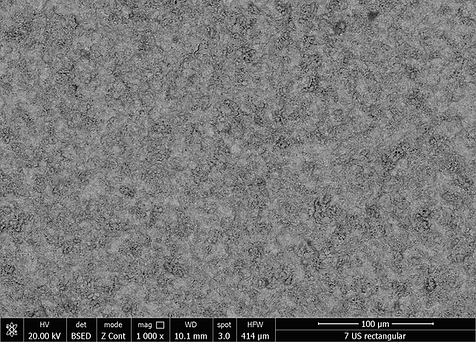

i7 Coating Microstructure

TYPICAL i7 COATING CROSS-SECTION MICROGRAPHS