Uniquecoat® M3™ HVAF Gun

Dual- or Single-Stage Combustion Flexibility

The M3 was the first dual-stage supersonic HVAF spray gun, delivering dense, high-performance carbide and metal coatings using standard HVOF-grade powders in dual-stage mode, while single-stage operation is optimized for Flash Carbide and fine HVAF powder applications.

The M3 gun features Uniquecoat’s proprietary dual-stage combustion principle, which creates an “afterburner” effect by extending the effective heating zone across two sequential nozzles. This configuration significantly enhances particle heating and increases both deposition efficiency and coating quality.

Compared to traditional single-stage combustion HVAF guns, the dual-stage combustion system delivers higher particle velocities and elevated particle temperatures, enabling the deposition of impermeable tungsten carbide coatings with hardness up to 1630 HV300 and negligible W₂C content when using HVAF-cut powders (5/30 µm).

The M3 also supports standard HVOF-grade powders (15/45 µm), producing coatings with typical hardness values of 1250–1350 HV300.

The M3 can also be equipped with interchangeable single nozzles for operation in single-stage combustion mode, similar to all other HVAF systems on the market, replacing the dual-stage setup. In this mode, the gun is optimized for fine and ultra-fine powders and is particularly effective for producing impermeable Flash Carbide coatings.

Example of Coating Performance

Tungsten carbide and chromium carbide coatings applied with the M3 using HVAF-cut powders (5/30 µm) have demonstrated 100% success in high-pressure gas permeability tests at 15,000 psi, confirming their impermeability and coating integrity.

M3

Key Features of the M3 HVAF Gun

🟢 Dual-stage combustion “afterburner” design – extends the effective heating zone for superior particle heating and higher coating density compared to single-stage HVAF guns

🟢 High coating performance – produces impermeable tungsten carbide (WC-10Co-4Cr) coatings with hardness up to 1630 HV300 and negligible W₂C content when using HVAF-cut powders

🟢 Versatile powder capability – efficiently sprays both standard HVOF powder cuts (15/45 µm) and HVAF fine cuts (5/30 µm) with high deposition efficiency

🟢 Configurable nozzle options – sonic or supersonic nozzles, as well as ceramic nozzles of various diameters and lengths, are available to match specific powder sizes and materials for optimal performance

🟢 Quickly configurable operation – interchangeable nozzles allow rapid conversion from single-stage combustion mode for spraying fine and ultra-fine powders to dual-stage combustion mode for processing coarse HVOF-grade powders

🟢 Proven impermeability – WC and CrC coatings have passed 15,000 psi gas-permeability tests with a 100% success rate, confirming coating integrity

🟢 Consistent quality – stable particle velocity and temperature ensure dense, high-hardness coatings with excellent repeatability

M3 Gun Configurations

The M3 comes equipped with both single-stage and dual-stage combustion nozzle kits, providing operators with the flexibility to quickly adapt to different powder types and coating requirements.

Single-Stage Combustion Configuration — Optimized for Fine & Standard HVAF Powders

The single-stage combustion configuration excels with ultra-fine powders such as 2/15 µm WC-CoCr, producing thin (15–30 µm), dense, and impermeable coatings with an as-sprayed roughness of Ra 1.2–1.6 µm — ideal for Near-Net-Shape applications and Flash Carbide coatings.

At the same time, it maintains high deposition efficiency with all conventional HVAF-grade powders (5/30 µm).

Dual-Stage Combustion Configuration — Optimized for Standard HVOF Powders

M3 HVAF Gun

The dual-stage combustion configuration delivers substantially higher heat input to powder particles compared with single-stage operation. By injecting additional fuel into a secondary combustion zone, it creates a staged-combustion effect that increases particle temperature without introducing additional oxygen into the process air.

This configuration is ideal for standard HVOF-grade powders (15/45 µm), producing dense coatings with superior hardness, adhesion, and overall coating quality.

Modular Flexibility — One Gun, Two Combustion Modes

Switch seamlessly between single-stage and dual-stage combustion setups in just minutes. From ultra-fine (<15 µm) Flash Carbide powders to standard (–45 µm) HVOF grades, one system covers the full range with maximum efficiency and superior coating quality.

M3 Demo Videos

M3 HVAF PROCESS DEMOSTRATION VIDEOS

M3 Jet & Powder Stream

FLOW DYNAMICS OF HVAF JET AND POWDER STREAM

Applications

EXAMPLES OF INDUSTRIAL APPLICATIONS

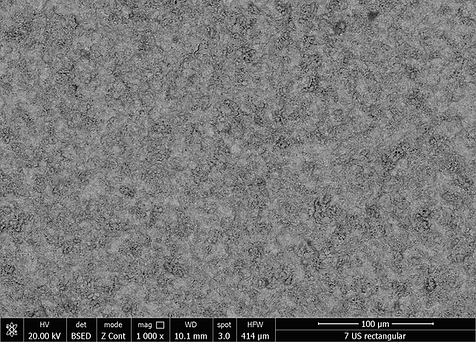

M3 Coating Microstructure

TYPICAL M3 COATING CROSS-SECTION MICROGRAPHS